Revolutionising Underwater Inspections: How MarineStream Is Changing Fleet Operations

Published: July 24, 2025

From port trials to fleet-wide compliance: How cutting-edge ROV technology is making underwater inspections safer, faster, and more reliable.

Hull inspections have always been expensive, risky, and time-consuming. Traditional methods—sending divers down in murky port waters or hauling vessels out for drydocking—often fall short when you're managing entire fleets.

The MarineStream team preparing ROV systems for underwater inspection operations

The MarineStream team preparing ROV systems for underwater inspection operations

MarineStream recently demonstrated something that could change everything. Working with Fremantle Ports and the Department of Primary Industries, they conducted what's believed to be the first voluntary assessment against Australia's proposed Anti-fouling Guidelines—right in port waters where cleaning is normally prohibited.

The trial used the pilot vessel Paddy Troy, with third-party environmental monitoring from O2 Marine. ROVs performed comprehensive underwater inspections, assessing biofouling and environmental risks in real-time.

The Problem with Traditional Inspections

Drydocking is becoming impossible. Limited capacity, massive costs, and vessels out of service for weeks. Meanwhile, sending divers down in poor visibility with outdated equipment creates safety risks and inconsistent results.

Traditional drydocking: expensive, time-consuming, and increasingly unavailable

Traditional drydocking: expensive, time-consuming, and increasingly unavailable

The regulatory landscape isn't helping. Stricter biofouling laws in Australia, Brazil, and New Zealand mean operators need bulletproof compliance documentation. One failed inspection can mean port denials, delays, and massive costs.

Enter ROV Technology

MarineStream's solution combines hardware with smart software. Instead of relying solely on divers, they deploy ROVs like the Deep Trekker REVOLUTION and PIVOT systems—equipped with 4K cameras, sonar, and positioning systems.

Marc piloting an ROV during hull inspection operations

Marc piloting an ROV during hull inspection operations

The difference is dramatic. What used to take 8-10 hours now takes 3. Multiple inspections can happen in a single day. And the data quality? Crystal clear, even in murky port conditions.

"When using ROVs, you remove people from hazards," explains CEO Adam Falconer-West. "ROVs handle the monotonous, repetitive work while divers focus on specialized tasks that require human expertise."

Real-World Results

During the Fremantle Ports project, Mat Harvey and the team completed a comprehensive pre-clean inspection in just 45 minutes. The ROV connected directly to MarineStream's digital platform, producing detailed reports with photographic evidence—all without putting a single diver in the water.

Mat and Marc analyzing real-time ROV data during inspection operations

Mat and Marc analyzing real-time ROV data during inspection operations

The platform streams live video to surveyors and regulators remotely, cutting approval times and reducing costs. Everything is geotagged, timestamped, and stored on blockchain for complete traceability.

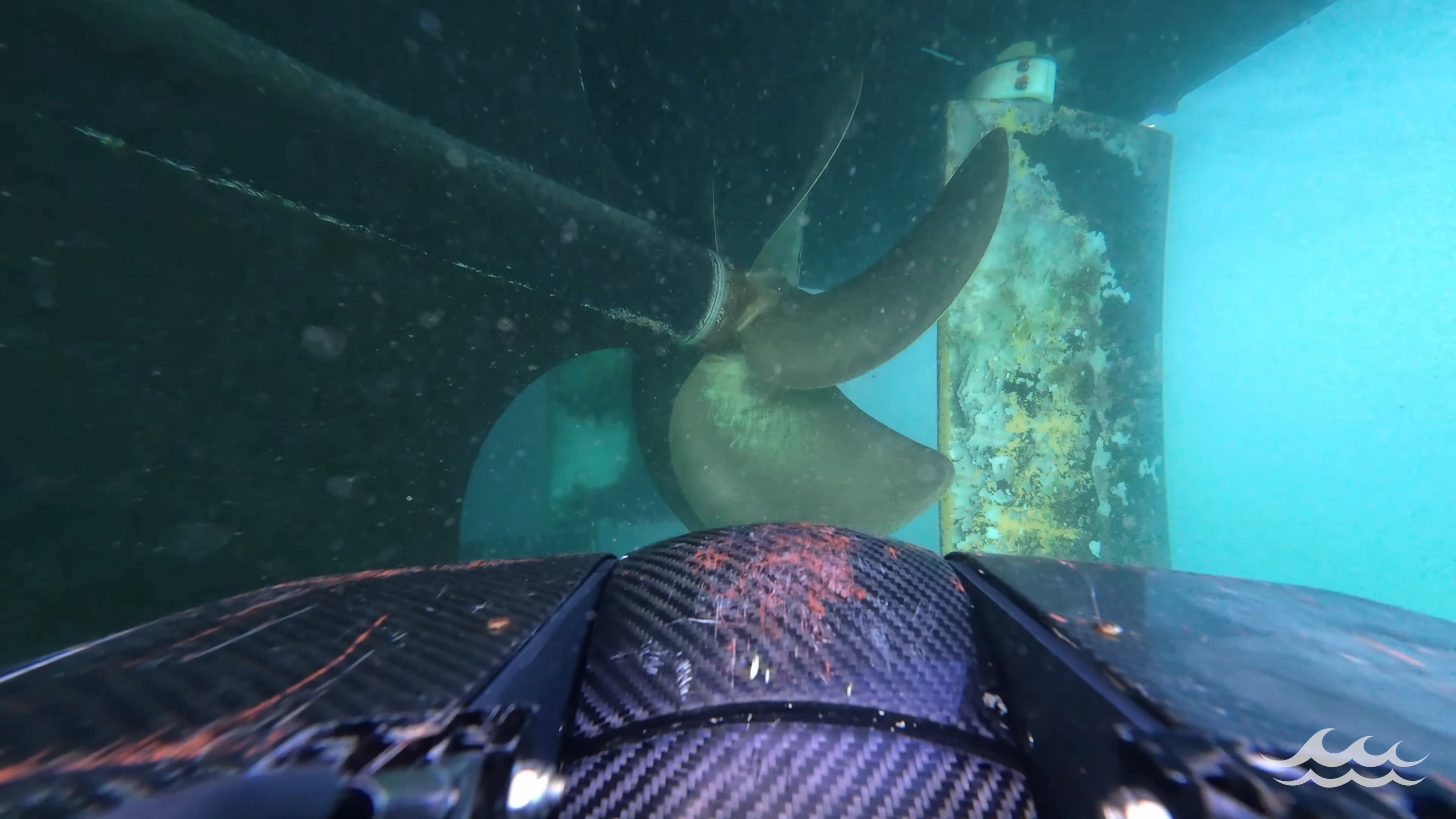

ROV's eye view: detailed propeller inspection impossible to achieve safely with traditional methods

ROV's eye view: detailed propeller inspection impossible to achieve safely with traditional methods

Two Types of Inspections, One Solution

MarineStream handles both UWILD (Underwater Inspections in Lieu of Drydocking) for classification societies and biofouling assessments for environmental compliance. Different requirements, but the same efficient approach.

Classification societies like DNV and ABS need structural integrity data. Environmental authorities want biosecurity compliance. MarineStream's system delivers both from a single inspection.

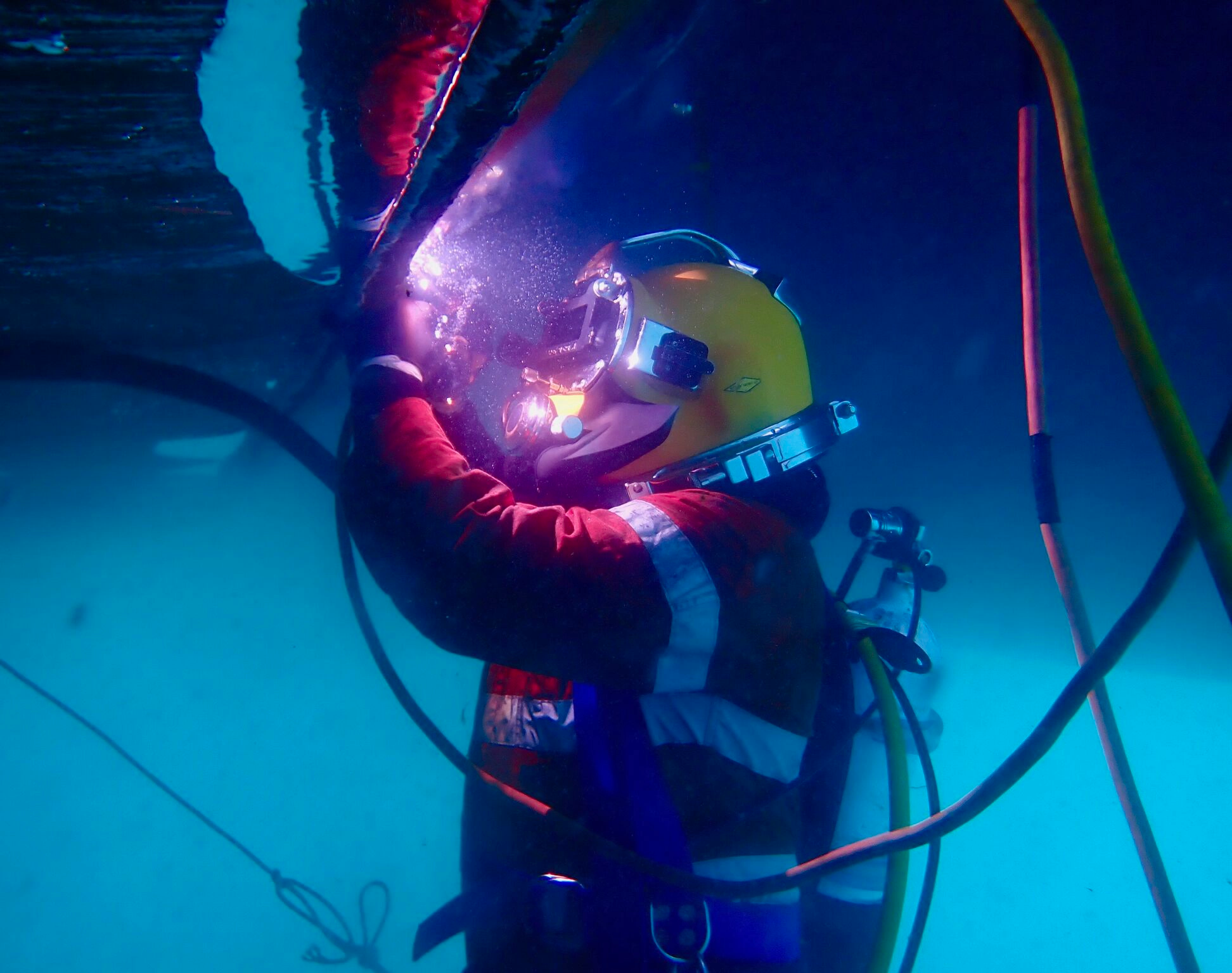

Commercial divers still handle specialized tasks while ROVs manage routine inspections

Commercial divers still handle specialized tasks while ROVs manage routine inspections

The Technology Stack

The MarineStream platform (app.marinestream.io) integrates with multiple hardware systems:

- ROVs: Revolution, Pivot, Photon, DTG3

- Crawlers: Clin Crawler, Vac Max Crawler

- Filtration: 5-25 micron systems with UV treatment

- Software: AI-powered reporting with blockchain compliance tracking

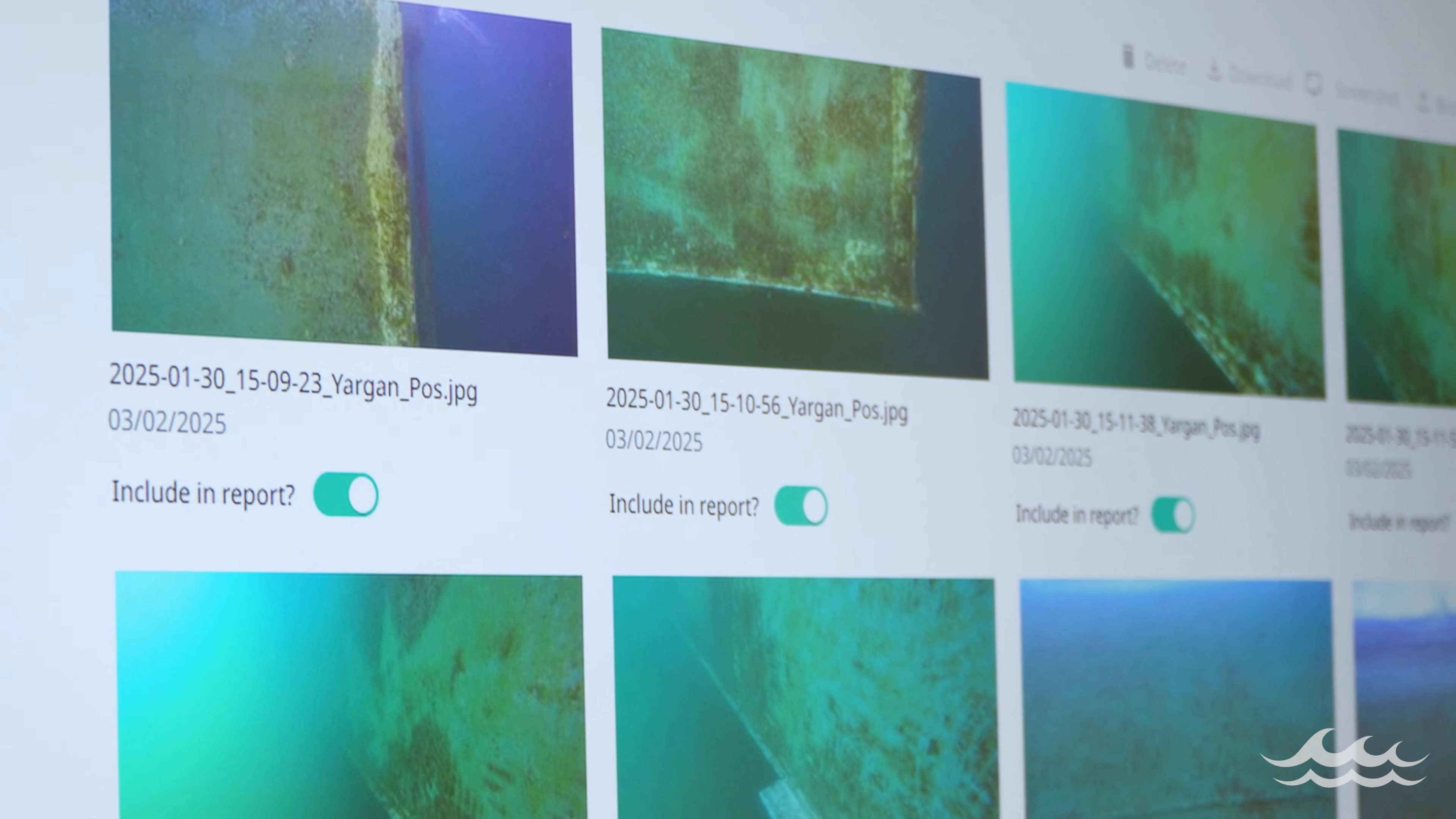

The MarineStream platform showing real-time inspection data and reporting tools

The MarineStream platform showing real-time inspection data and reporting tools

"MarineStream has created a complete framework for end-to-end biofouling management," notes Serena Brown, Global Business Development Manager at Deep Trekker. "The hardware ensures reliable data capture that supports the entire compliance process."

Scaling Across Fleets

For large operators managing dozens of vessels, consistency is everything. MarineStream's approach standardizes inspections across entire fleets, regardless of location or local regulations.

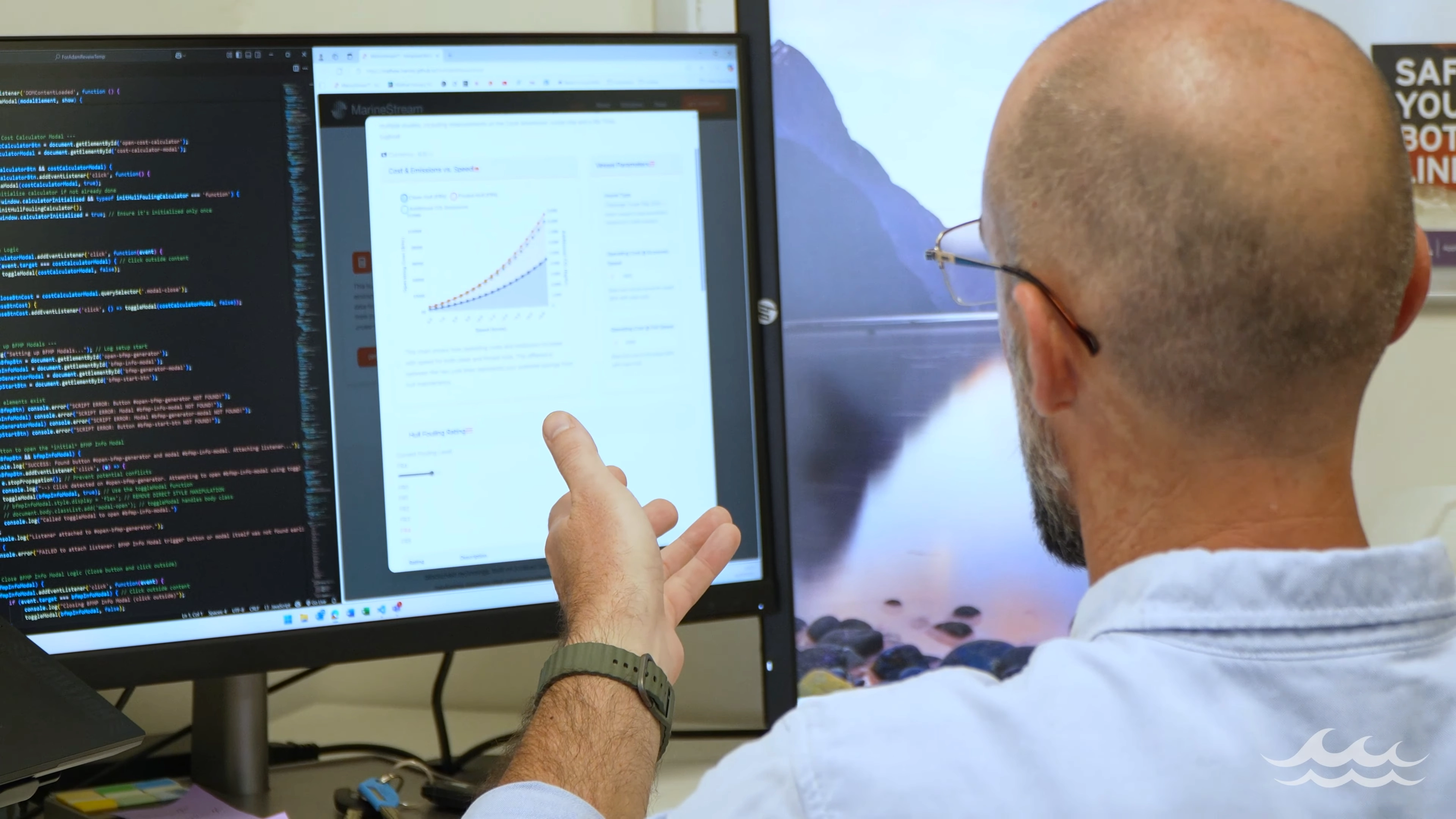

Mat configuring ROV systems for multi-vessel fleet inspections

Mat configuring ROV systems for multi-vessel fleet inspections

The system works globally. A vessel inspected in Australia uses the same protocols and generates the same quality reports as one inspected in Singapore or Rotterdam. Regulators get familiar documentation formats, and fleet managers get consistent data.

Aerial view of port operations showing the scale of modern maritime logistics

Aerial view of port operations showing the scale of modern maritime logistics

What's Next

As environmental regulations tighten and drydocking capacity shrinks, in-water inspections aren't just convenient—they're essential. MarineStream is positioning itself at the center of this shift.

"Ports face tighter turnaround times and environmental scrutiny," says Falconer-West. "Our digital platform and hardware integrations make a real difference."

The Fremantle Ports trial proved the technology works. Now it's about scaling up and helping the maritime industry transition to safer, more efficient underwater operations.

About MarineStream

MarineStream is an Australian marine services provider delivering comprehensive underwater inspection, maintenance, and biofouling solutions. Based in Henderson, Western Australia, they serve defense, port, and commercial operators with over a decade of experience in commercial diving and subsea operations.

Learn more: app.marinestream.io

Published by MarineStream - Advanced Underwater Asset Management Solutions